Interdisciplinary product development methods to create an air-care product with triple-bottom line sustainability

Procter & Gamble

highlights

- Integrated Product Development course at Carnegie Mellon

- Developed product to protect commuters from degrading urban air quality

- Performed primary research with users in multiple transit systems

- Led interdisciplinary team during design phase

- Presented to P&G executives

Proctor and Gamble asked our team to think about transforming the air care category in a way that incorporated the company's sustainability goals throughout the process. We followed an integrated product development approach outlined in Creating Breakthrough Products by Craig Vogel and Jonathan Cagan, one of our professors.

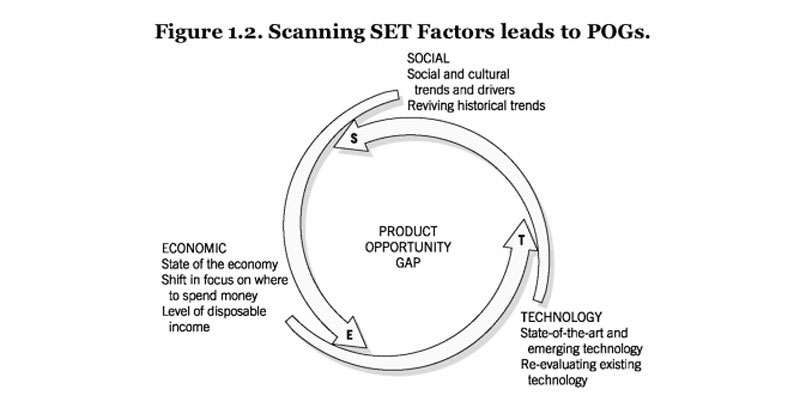

SET Factors

This method of trend categorization helps brainstorm new product opportunities

We researched macro social, economic, and technological trends as well as P&G's core competencies and values to identify an area of opportunity for new product development. We found that public transit ridership in the US is at the highest it has been in 50 years, likely driven by the economic recession and growing urbanization of the country. This congestion has come with a deterioration in air quality, among other things. From these findings, we focused our scope on the opportunity to create a portable product that allowed individuals to control the quality of the air in their immediate vicinity as they experienced varying environmental conditions throughout the day.

Air vent in New York subway system

This still frame from our research video highlights the severity of the air quality around public transit systems

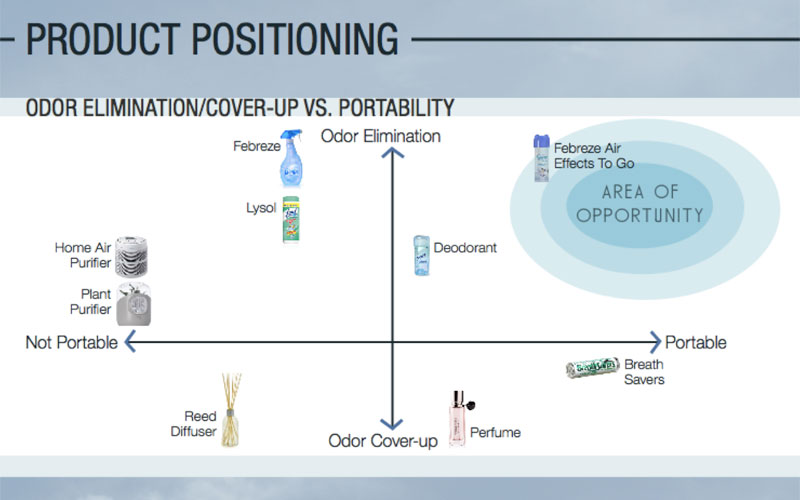

Product positioning

We held in–person interviews and an electronic survey about air care, then asked 10 folks to record daily logs of their are care experience throughout the day. We found that users expect air care products to eliminate odors while also providing health benefits. Specifically, people pointed to other people's personal odors and cigarette smoke were the worst air–offenders and that the biggest difficulty with odors were on public transportation and while moving throughout the city.

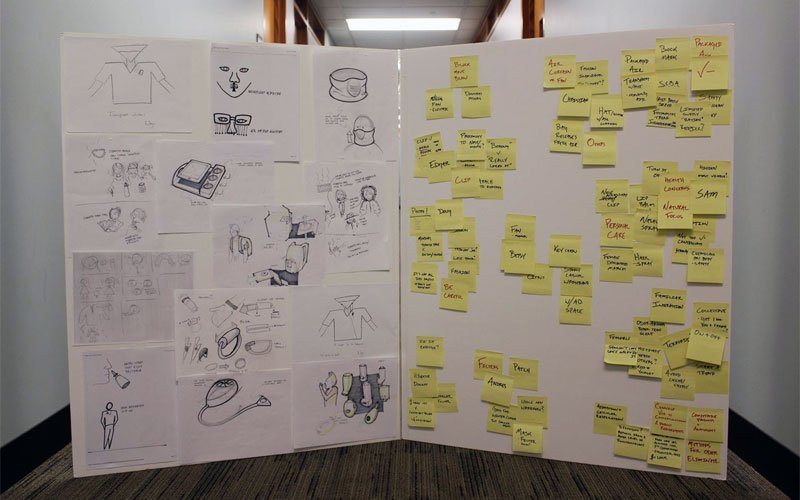

With this information in hand, I led the team through concept generation methods. We went through 4 rounds of generating product concepts and then testing those concepts with users. Sketches and prototypes were lo–fi at first for the interdisciplinary team to generate ideas quickly. As rounds of testing went on, the designers and engineers worked together to build higher fidelity form models and functional prototypes.

The team's concept board

Team members from all backgrounds brainstormed and sketched product concepts. Favorites were preserved on this concept board for reference.

Prototypes

We created rough physical models of each concept

In context research

We took our prototypes into the field to test our ideas with real users

In the final phase we worked to specify the characteristics of our final product concept. We took our models on the road to test in the New York City subway system and the Chicago El. We built CAD models to visually communicate our concept, manufacturing plans to prove feasibility, and held a conjoint survey along with qualitative field research to decide on the specific, final features of the product. The team's MBAs led us through a sensitivity analysis, cost and revenue estimates, then estimated the project's net present value. We presented our final product concept to a team of P&G executives. ❦

Packaging rendering